Quality Control

Production link

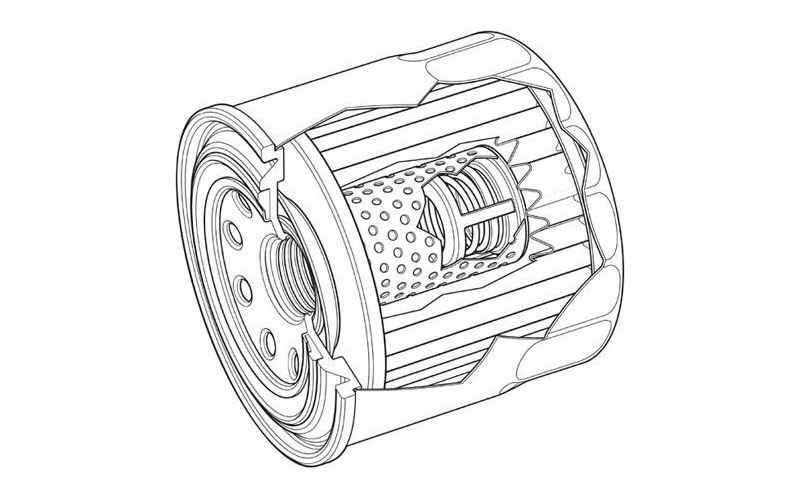

First of all, Juxuan carried out strict screening in the procurement of raw materials. The selection of high-quality filter paper and sealing materials fundamentally ensures the filtration performance and sealing of the oil filter. In addition, Juxuan will also conduct quality inspection of the purchased raw materials to ensure that the quality of raw materials meets the production requirements.

In the production process, Juxuan has implemented strict process control. From the folding of the filter paper, the installation of the seal ring to the assembly of the product, every link is strictly inspected and tested. In addition, Juxuan has also introduced advanced production equipment and technology to continuously improve production efficiency and product quality. Through the implementation of total quality management, Juxuan not only improves product quality, but also effectively reduces the generation of unqualified products.

Quality inspection and after-sales

Before leaving the factory, Juxuan will carry out a comprehensive quality check on the finished product. Including appearance, size, sealing performance, filtration performance and other aspects of the test. Only products that have been strictly tested and meet quality standards will be allowed to leave the factory. In addition, Juxuan will regularly carry out spot checks on products to ensure the consistency of product quality.

In addition to product quality control, Juxuan also attaches great importance to after-sales service. To provide customers with timely technical support and solutions, to ensure that customers in the use of the process of the problem can be solved in time. Through high quality products and perfect after-sales service, Juxuan has won the trust and praise of many customers.